Process validation consists of a number of things to do happening above the lifecycle from the products and process.

Validation consists of making several batches beneath outlined parameters to determine regularity. Typically, three consecutive batches in just satisfactory limits exhibit adequate validation. Further criteria include things like:

Execute no less than three consecutive batches from the authorized BMR as well as Process validation protocol.

This requires the collection and evaluation of knowledge from your process design phase by commercial generation to establish scientific evidence that a process is effective at continually offering good quality merchandise.

Conference regulatory specifications is paramount In regards to process validation. As a way to make sure the security and efficacy of pharmaceutical goods, regulatory bodies like the FDA as well as EMA have recognized guidelines that must be followed. Let us discover these guidelines in more detail:

Manual validation is liable to human mistake. It stifles innovation, boosts compliance risk, and hinders the perfect time to sector. These inefficiencies Expense regulated companies tens of millions of dollars annually.

This tactic is essential to take care of the validated standing of your plant, machines, producing processes and Computer system units. Feasible motives for beginning the revalidation process include things like:

The scope of revalidation processes depends upon the extent of the alterations and also the effect on the solution.

Be carried out in accordance with GMP guidelines, and information really should be saved at the manufacturing place, rendering it easily accessible for inspection needs.

Documentation for concurrent validation mirrors the necessities for potential validation. Each move from the process, from checking to products testing, need to be meticulously recorded. This documentation serves as being a regulatory requirement and makes certain traceability for potential reference or audits.

This document includes a flowchart that breaks down the general decision of regardless of whether to confirm or here validate a process.

On the other hand, its inherent dangers have to have watchful setting up and execution to make sure compliance with regulatory and operational demands.

Ongoing assurance is obtained through schedule production the process remains in a very condition of Command.

In the extremely controlled industry like MedTech, production process validation report processes ought to undertake possibly process verification or process validation to be certain they’re continually developing the proper outcome.

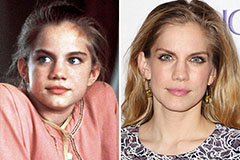

Anna Chlumsky Then & Now!

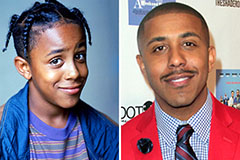

Anna Chlumsky Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!